News

360 mandate for the Énercycle biomethanization plant

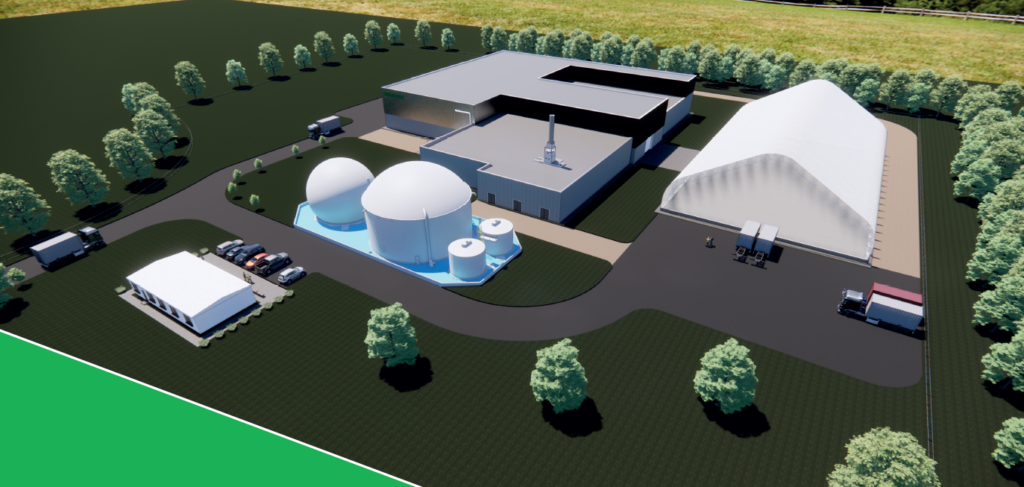

Last summer, Énercycle, the waste management authority comprising together 37 municipalities in Mauricie, officially entrusted the Energere-Convertus consortium with the mandate for the construction of a biomethanization and composting plant located in Saint-Étienne-des-Grès. This is a 360 degree project according to the design-build-finance-operate-maintain (DBFOM) approach, and is planned to be put into operation by 2026 with contractual operation over a period of 20 years.

The objective of this major project: recycle and reclaim 35,000 tonnes of residual materials collected from citizens – from the classic brown bin – to transform them into natural biogas. This initiative helps reduce waste, and more importantly, produces green energy with low carbon footprint.

WHAT IS BIOMETHANIZATION?

Biomethanization is a natural biological process in which microorganisms decompose organic matter anaerobically (without oxygen), such as food waste and citizens’ green waste (in short, everything that ends up in the brown bin), to produce biogas or biomethane, and a residue called digestate.

Biogas, mainly composed of methane, carbon dioxide and water, once purified, becomes renewable natural gas (RNG), used as a renewable energy source for the production of electricity and heat. RNG is also recognized by Natural Resources Canada as a renewable energy and a clean fuel that will make it possible to achieve the new net zero emissions targets announced by Canada1.

Digestate is an organic residue rich in nutrients which, after aerobic treatment (with oxygen), is transformed into compost, which can be used as fertilizer in agriculture.

In other words, biomethanization is an efficient process for reducing greenhouse gas emissions on two levels:

- On a direct level: by replacing fossil energy (natural gas = methane) with renewable energy through the recovery of organic waste.

- On an indirect level: by diverting organic waste from landfills. The decomposition of organic matter in a landfill generates biogas which would partly be released directly into the atmosphere. The majority of biogas is captured and transformed into renewable natural gas in the WAGA Energy plant then entered into the Énergir gas network.

THE CHALLENGES TO ADDRESS

There are many challenges to face as part of this complex project, starting with the process itself, which, although widespread in Europe, is still nascent in Quebec. The dry biomethanization and composting plant in Saint-Étienne-des-Grès will be the first of its kind in Quebec.

Among various other challenges, there is:

- A design that must meet the highest environmental standards, particularly in terms of energy efficiency, atmospheric emissions, water treatment, odours and noise.

- A design that must take into account the growth of needs over time.

- Connecting and managing technological partners from all disciplines.

“It is a great pride to be able to contribute to efforts to reduce greenhouse gases in symbiosis with renowned partners, to a large, positive project in Quebec which will, I hope, inspire many other players in the fight against climate change,” Mario Geoffrey, Director of Biomethanization at Energere points out.

“We are delighted to partner with Énergère for the development of this state-of-the-art organic waste treatment facility in the Mauricie region,” said Michael Leopold, CEO of Groupe Convertus. “We’re passionate about working with forward-thinking companies and municipalities like Mauricie, who share our commitment to treating waste in the most sustainable way possible. This partnership marks an important milestone for Convertus as we establish our first facility in Quebec.”

THE PRINCIPAL PARTNERS

Such a project can only be carried out by uniting different partners with a common vision. Énergère and Convertus Group orchestrated the project, which will combine the strengths of each of the key players.

- Energere/Convertus Group: Project promoters with extensive expertise, particularly in DBFOM projects with performance guarantees.

- WTT: Technological partner for the biomethanization and composting equipment component.

- Ainsworth Inc.: Construction and HVAC component.

- Les Entreprise QMD Inc.: Construction project management.

- Lemay Inc.: Architectural service.

- EXP: Consulting engineering service at the civil, structural, mechanical, electrical, and fire protection modeling level for environmental studies and beyond.

THE PROJECT IN KEY STATS

- 35,000 – The number of tons of organic materials sorted at source (brown bins) supplied by Énercycle that the new plant will be employed to convert into biogas.

- 6 500 – The number of truckloads of residue received per year.

- 37 – The number of municipalities in Mauricie that will provide organic waste from brown bins to convert it into biogas and compost.

FUNDING AND GRANTS

In March 2023, the Quebec government presented its investment plan as part of the 2024-2034 Quebec Infrastructure Plan. In this context, a request for $14.5 million has been sent and is being processed for the project to construct the biomethanization plant in Saint-Étienne-des-Grès2.

At Energere, we have a team dedicated to grant management which takes charge of oversight, optimizing, supporting and monitoring financial aid for each decarbonization and energy efficiency project.

THE NEXT STEPS

The project is currently in the design phase. Construction itself will begin in spring 2025 for commissioning in mid-2026. There is then a performance test period lasting approximately 2 months for commercial commissioning in September 2026.